DOT Brake Fluid vs. Mineral Oil - and the Winner is..

DOT Brake Fluid vs. Mineral Oil - and the Winner is..

Brake fluid is an essential part of the hydraulic braking system. Without it, or without enough if it, the forces you apply at the brake lever would not be transferred to the caliper, pads and rotor.

One of the great debates and areas of confusion surrounding brake fluid is which brake fluid is superior?

Most of you will know that hydraulic brakes are designed to use one of two main types of brake fluid - DOT fluid or Mineral Oil, and which one you pick is not a choice made by you or me, but rather by the brake manufacturers themselves. But which brake fluid is best and why do we have two to begin with?

Well we're going to try and answer those questions today. I'll explore these brake fluids in detail, sum up their advantages and disadvantages and explain why the experts believe their choice of fluid is best for us riders. Let's get started..

The Role of the Brake Fluid

If you've read How Hydraulic Brakes Work you will know that brakes slow us down by turning kinetic energy into heat by using friction.

Brake fluid is only one of several vital components which enable hydraulic brake systems to work effectively. Its job is to transfer the input forces you create at the master cylinder (lever) to the caliper pistons. This is possible as fluids are generally incompressible.

The brake fluid also has to resist, as far as possible, the high temperatures created by the braking forces.

Types of Brake Fluid

There are two types of brake fluid used in hydraulic mountain bike brakes today:

- DOT Fluid

- Mineral Oil

DOT Fluid

Certainly the most commonly used brake fluid in use today, due to its wide use in the automotive industry, is DOT fluid. All DOT fluids (with the exception of DOT 5) are made up of a poly-glycol base.

Glycol-based fluids consist of a mixture of ingredients with as many as ten separate substances making up the final product. These substances can be broken down into four key components:

- A lubricant, such as polythene or polypropylene, to keep parts moving freely - 20-40%.

- A solvent diluent, usually glycol ether, which determines the fluid's boiling point and viscosity and accounts for 50-80% of the fluid.

- A modifier-coupler, which changes the amount of swelling of exposed rubber parts.

- Inhibitors, to prevent corrosion and oxidisation.

DOT brake fluid is required to meet strict standards and specifications set out by the Society of Automotive Engineers and the Department of Transportation (DOT) - hence the name. These standards centre around maintaining brake fluid performance in a range of temperatures (high and low) and also specify the minimum boiling temperatures which the fluid manufacturers must adhere to.

Boiling Temperatures

One of the main differences separating the various classes of DOT fluid is their boiling temperature (or boiling point). This refers to the temperature where the brake fluid will start to boil or vapourise inside the brake system. This is caused by the intense heat created after prolonged, heavy brake use and has an adverse effect on the performance of the entire brake system.

What happens when brake fluid starts to boil?

When brake fluid absorbs enough heat it boils and vaporises. It turns from a fluid into a gas. This gas can lead to complete brake failure in hydraulic systems. Suddenly the incompressible nature of the brake fluid, which produces the firm lever feel that we know and trust, has disappeared due to the introduction of compressible gasses in the brake system.

Now all of the input forces normally created by squeezing the brake lever are lost as they go into compressing the air bubbles within the fluid instead. Now the brake fluid can no longer transfer these forces to the caliper leading to brake failure - this is known as 'fluid fade'.

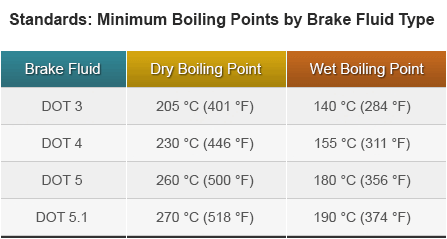

Let's take a look at the minimum boiling temperatures of DOT brake fluid as specified by the regulatory bodies.

Note that these are the minimum boiling temperatures as outlined by the Department of Transportation and do no always reflect the true boiling points of the different brands of DOT fluid on the market today. Fluid manufacturers can and do improve on these temperatures with some brake fluids reaching dry boiling temperatures well in excess of 300°C/572°F.

What is meant by dry and wet boiling points?

The Dry Boiling Point of brake fluid refers to the boiling temperature of fresh, new brake fluid from an unopened container. Whereas the Wet Boiling Point is defined as the temperature DOT brake fluid will begin to boil after it has absorbed 3.7% water by volume. DOT brake fluid will reach this level of water volume after roughly 2 years of service, which is why it is advisable to renew your brake fluid every year.

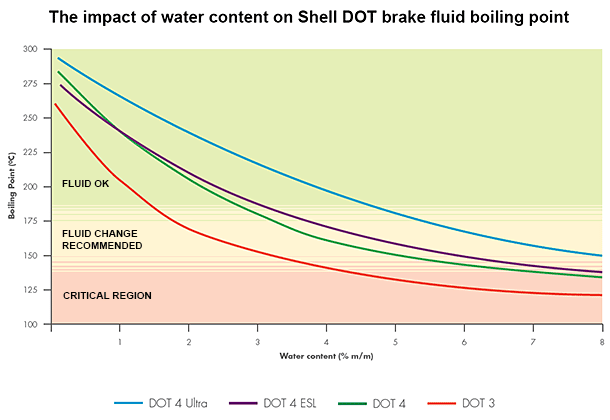

The effects of this water content over time are better illustrated by the graph below. This graph is taken from Shell and gives an overview of the declining effect water content has on its range of DOT 3 and DOT 4 brake fluids.

Let's remember that the Department of Transportation specify the minimum wet boiling point of DOT brake fluids after absorbing only 3.7% water content (roughly 2 years service). In the graph above we can see that the boiling points of the various Shell DOT fluids decline much further over longer periods of time. When brake fluid reaches 8% water content the boiling point of Shell DOT 3 brake fluid has been reduced almost to that of water - 100°C!

So where does this water come from?

Glycol based fluids are hygroscopic which means they absorb water/moisture from the environment at normal atmospheric pressures at a rate of 2-3% per year. This process is exasperated in more humid conditions and climates.

This water content finds its way into the brake fluid via microscopic pores in brake hoses, seals, joints and seams. As we've learnt, water mixed with DOT fluid has an adverse effect on the brake fluid by reducing its boiling temperature and therefore reducing its performance.

Hell no H2O!

Hold on a second, although we've just made water out to look like your new worst enemy, the hygroscopic nature of DOT brake fluid is actually an advantage in a major way.

As water enters the system, instead of pooling in low spots (such as the caliper), due to its weight in comparison with brake fluid, it is dispersed throughout the whole of the brake fluid. This helps to keep the boiling point of the entire brake fluid high rather than having pools of water in the system which will boil much sooner than the rest of the brake fluid.

It also prevents localised corrosion of internal parts which can be caused by water pooling in the brake system.

So what about DOT 5 brake fluid?

DOT 5 brake fluid (not to be confused with DOT 5.1) is fundamentally different than the rest of the DOT fluid range in that it is silicone based brake fluid.

It was originally introduced to give a higher boiling temperature over glycol-based DOT 4 brake fluid. Purple in colour and sometimes referred to as 'synthetic brake fluid', DOT 5 is not compatible with any of the glycol-ether based DOT fluids that we've been focusing our attention on so far.

Although tests have been carried out by the various hydraulic mountain bike brake manufacturers, DOT 5 has so far not proven itself to be a better alternative to glycol-ether based fluids used in hydraulic mountain bike brakes today.

It is also more compressible than the other DOT brake fluids which can lead to a sluggish or spongy brake lever (or pedal) feel, and therefore requires special design considerations when used in brake systems.

Furthermore DOT 5 is hydrophobic and does not absorb water from the atmosphere like regular DOT brake fluid will.

So what is it good for?

Due to its hydrophobic properties it has a very long life-span meaning low maintenance and fewer fluid changes. It is also kinder to paintwork unlike corrosive glycol-ether based DOT fluids.

A good example of its use is in military vehicles which can be stored for long periods of time but need to be ready to be used at a moments notice. It is also favoured by some owners of classic cars for vehicles which may also rarely be used on the roads.

Mineral Oil

Unlike DOT brake fluid, Mineral Oil brake fluids are not governed by any standards or regulatory body, therefore the technical information on the various substances that contribute to their make-up is usually hard to come by. The likes of Shimano and Magura have no doubt spent a lot of time and money refining their proprietary Mineral Oil brake fluids so you can understand why there is a degree of secrecy on the subject.

But is the lack of a governing 'rule book' for Mineral Oil bad thing? Here's what Shimano have to say:

| "We actually see this as a major advantage of using Mineral Oil. We don't have to trust anyone else's testing standards for the fluid they make. Since every Shimano brake uses Shimano brake fluid, we have complete control over the process and can assure consistent performance." |

| - Nick Murdick, Lead Multi Service Technician - Shimano |

It's a convincing argument. It's easy to understand why a huge organisation like Shimano, with their kind of budget, would want complete control over the production of their brake fluid.

Mineral Oil Boiling Temperatures

Ok, so now we're getting down to the nitty gritty, this is where Mineral Oil differs greatly from DOT brake fluid.

Unlike DOT fluid, Mineral Oil is hydrophobic and does not absorb moisture from the environment. This means that there are no wet or dry boiling temperatures to worry about, the boiling point stays constant and never drops. That's the good news.

The bad news is that any water that does enter the brake system, via seals or microscopic pores in the lines etc., will effectively reduce the boiling point of the whole brake system to that of water - just 100°C. This is because as the fluid repels any water ingress, it causes it to pool at low points within the brake system, usually the caliper, since water is heavier than brake fluid it will settle at the lowest point. This is worrying because the fluid in the caliper is more susceptible to high temperatures as it's at the business end of the brake, where the friction is created.

You might think that since the boiling point of Mineral Oil never drops then the trade-off must be that it must start much lower than DOT fluid, after all you can't have the best of both worlds can you? Well recent discoveries suggest that might not be the case. Let's take a look at some of the figures we know of.

Brake Fluid Shelf Life

DOT Brake Fluid

The shelf life of glycol-based DOT brake fluid is very poor due to its hygroscopic properties, which is why every bottle should come with an air tight foil liner covering the opening. As soon as this air tight seal is broken it will start absorbing moisture from the environment and the boiling point will begin to drop.

Castrol recommends that DOT fluid in previously opened containers should be discarded after 12 months. In our opinion it would be unwise to use DOT fluid from a bottle which has been open for more than a few months, unless you have no other alternative.

To reduce large quantities of wasted brake fluid, use DOT fluid from smaller 100ml bottles. 100ml is enough to bleed a set of brakes (front and rear) 2-3 times.

Mineral Oil

Since Mineral Oil is hydrophobic and does not absorb water from its environment, one of the great advantages it has over DOT fluid is that once opened it can be stored indefinitely.

Compatibility Between Brake Fluids

So just which brake fluids can you mix without causing harm to your brake system? Let's take a look at the chart below.

As you can see all of the glycol- based DOT fluids (3, 4 & 5.1) are fully compatible with each other and can be readily mixed or swapped without adversely affecting the brake's performance or its characteristics. The main change will come in a decrease or increase in the boiling point of the brake fluid as a whole.

For example if you introduced DOT 3 into a brake previously filled with DOT 5.1 then you will probably be left with a brake fluid with a lower boiling point. I say 'probably' as it depends on the service life of the older fluid but you get the idea - not a great deal can go wrong mixing glycol-based DOT fluids.

Silicone DOT 5, as we mentioned earlier, is not compatible with any of the other DOT fluids, nor is it able to be mixed with Mineral Oil brake fluid. Since there is no hydraulic mountain bike brakes using DOT 5 fluid we won't worry too much about it. The main thing to remember is it should never be confused with DOT 5.1 as they are fundamentally different brake fluids.

What about compatibility between Mineral Oil brake fluids?

Here's where things get a bit hazy. Unlike DOT fluid which is pretty clear cut, mixing Mineral Oils is an altogether different story.

We at EBS had believed that all Mineral Oils manufactured for use in hydraulic brakes (not the stuff you can buy from the local pharmacy or drug store) are compatible with each other, but our earlier thoughts were questioned after reading a very informative Q&A session conducted by the good folks at Bike Rumor recently.

7 questions regarding brake fluid and its implications for use with hydraulic road disc brakes were directed at the top brake manufacturers and the unedited replies were published.

One Shimano representative revealed that no third party Mineral Oil has ever been sanctioned for use in Shimano brakes - this we expected to hear as Shimano will of course be recommending you use their proprietary brake fluid. However he went on to state, with 'absolute certainty', that 'Magura fluid will destroy Shimano brakes in a very short amount of time.'

This got us thinking. Are Shimano simply trying to put the frighteners on people so they use nothing but Shimano's own branded Mineral Oil? We contacted Will Miles of Juice Lubes, who manufacture a range of lubricants, cleaners and brake fluids (including Mineral Oil), to get their take on this and here's what they said when it comes to compatibility between Mineral Oils:

| "Our view is quite simple in that having tested our Mineral and DOT oil in all Mineral and DOT systems we are happy to recommend it for any brand of brake manufacturer including Shimano. We have sold thousands and thousands of units worldwide and never had any problems reported. Clearly the manufacturers have a vested interest in recommending and insisting that consumers use only there oil and to be fair why wouldn't they? It does make perfect commercial sense and does allow them to maintain quality control standards so I can completely understand there point of view and stance on the matter. As Juice Lubes is a non-OE supplier, all we can do is test our products, ensure they are of the highest grade and work as intended - which is exactly what we do." |

| - Will Miles, Juice Lubes |

Thanks Will. After thousands of units sold and no problems reported perhaps Shimano could be accused of exaggerating slightly - but that's just my view. In any case, one thing to remember at all times when considering swapping out your Shimano or Magura proprietary Mineral Oil is that you may void the brake's warranty in the process. You've been warned.

Which Brake uses which Brake Fluid?

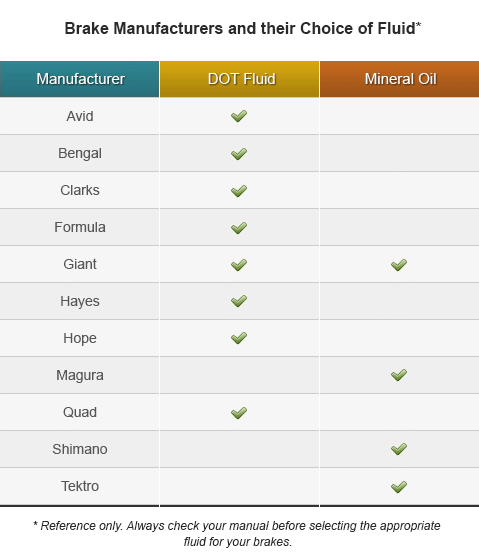

So which brake fluid should you be using with your brake set? Well that of course depends on your brake model. You will usually find the type of fluid your brake was designed to use printed somewhere on the lever assembly or reservoir top cap. This makes it easy to identify and saves you from making the fatal mistake of introducing the wrong fluid and destroying your brake's internal seals.

But while we're on the subject let's take a look at which way the various brake manufacturers lean when it comes to brake fluid choice. Take a look at the table below.

From that picture it's clear to see that DOT fluid is used by the vast majority of hydraulic brake manufacturers on the bike scene, however does that necessarily mean it's the best choice for users? Let's zoom out a little and take a look at the strengths and weaknesses of each fluid.

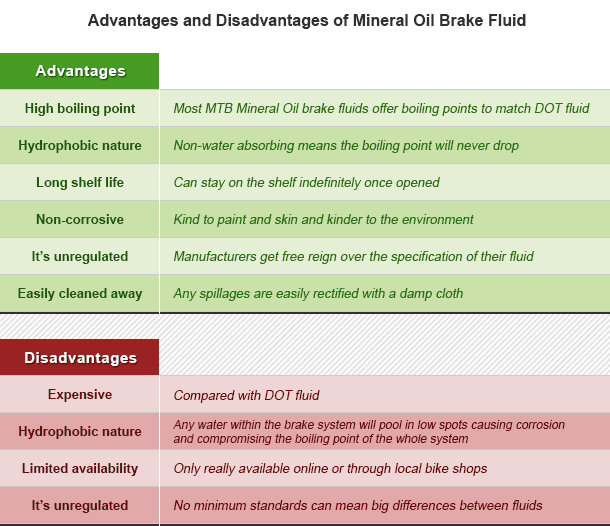

Advantages and Disadvantages

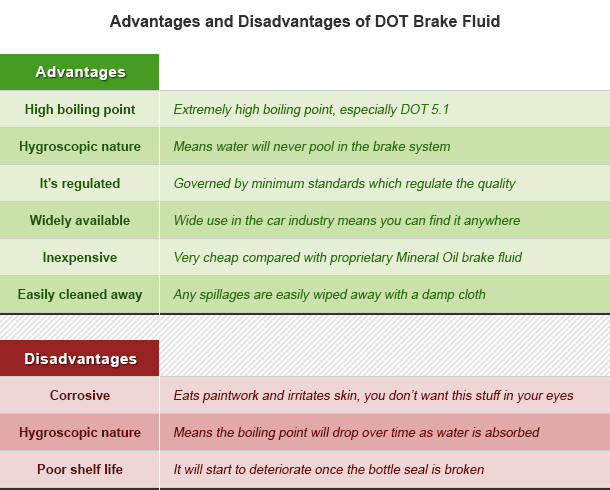

So here it is. This is where I'm going to give you an overview of the advantages and disadvantages of each brake fluid as I see them. Let's start with DOT fluid and remember that the points below apply to glycol-based DOT fluids only, we're excluding silicone DOT 5 as it is not used in any hydraulic cycle brakes that we know to.

As you can see, there are a lot of positive points about DOT brake fluid, not least the fact that it can be found pretty much anywhere at less than half the price of Mineral Oil. There's good news and bad news when it comes to its water-absorbing properties, that is why you'll find I have entered it in both tables to show both sides of the story.

On this particular point I personally feel that the benefits massively outweigh the drawbacks. Changing your brake fluid annually to conquer the drop in boiling point is a small price to pay to avoid having water pooling in your brake system.

Also the fact that it is regulated by the federal government means that the brake manufacturers can concentrate on building brakes instead of formulating brake fluid, and be safe in the knowledge that the DOT fluid they're designed to be used with is of consistent high quality regardless of who should manufacture it.

A huge disadvantage of Mineral Oil, or proprietary brake fluid, is the cost. As it is one-of-a-kind, there's no competition (as such) and the warranty says you should use it, they can basically charge what they like for it - and they do. Not cool!

In contrast to DOT brake fluid, Mineral Oil is not a regulated fluid. This means that the likes of Shimano and Magura have the added freedom when it comes to its manufacture. Shimano certainly see this as an advantage as they 'don't have to trust anyone else's testing standards' and can pretty much guarantee the results. A sceptic would also point out that they can also make money off the back of fluid sales as an extra revenue stream.

Another great thing about Mineral Oil is that it does not destroy your paintwork, something which is very important as bikes and bike gear gets shinier by the week. Don't blemish that bling now! :)

And the Winner is..

So there it is. A break down of the two brake fluids in use in hydraulic mountain bike brakes today. Both very different in their make-up, and with their own set of characteristics but ultimately performing the same role. By now you will appreciate that there is more to the great brake fluid debate than simply discussing boiling temperatures.

Which ultimately leaves only one question - which one is best?

Well, why don't you tell us? You've heard the evidence, now it's time to choose your overall winner using the poll and telling us why in the comments below.

Sources:

Bike Rumor - Tech Speak: Brake Fluid Break Down & Implications for Road Disc

Castrol - Product Data Sheet: Super Response DOT 4

Valvoline - LHM Plus product information and data sheet

Society of Automotive Engineers International - Standard J1703: Motor Vehicle Brake Fluid

Code of Federal Regulations - Standard No. 116; Motor vehicle brake fluids

Image credits: Shell, Tord Mattsson